Metal processing and shaping

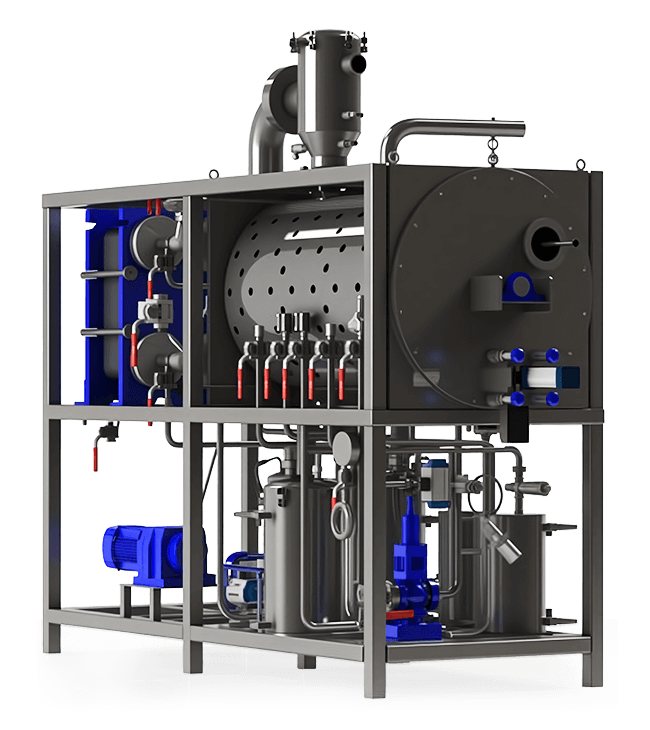

Metal cutting, forming, stamping and surface finishing generate stable oil–water emulsions that are difficult and costly to handle. Typical contaminants include mineral oils and additives, fine metal particles, surfactants, and suspended solids.

Pharmaceutical industry

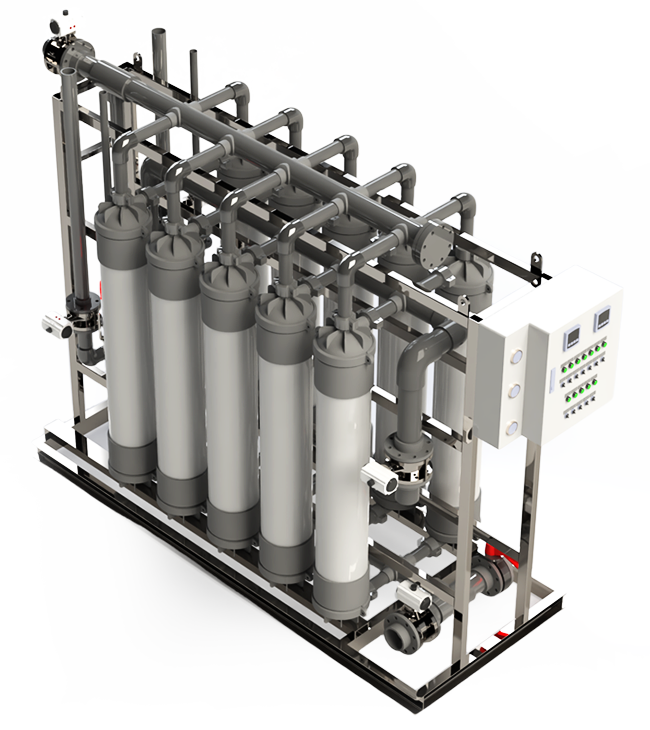

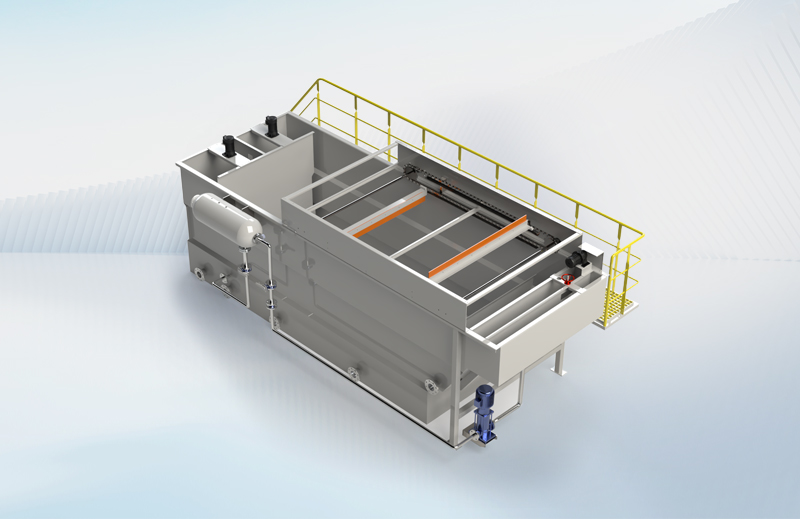

Deepflow provides complete solutions to handle these challenging streams, combining physical-chemical pretreatment, membrane separation, and vacuum evaporation for reliable, compliant, and sustainable operation.

Textile industry

Textile dyeing, washing, and finishing lines produce wastewater containing colorants, surfactants, fiber residues, sizing agents, and salts. These streams are often strongly alkaline or acidic, and highly variable in temperature and organic load.

Printing & Photography Industry

The printing and photography sectors generate wastewater containing inks, solvents, surfactants, developers, fixers, and residual metals (silver, chromium, nickel).

These effluents are often colored, oily, and highly variable, requiring advanced treatment to ensure compliance and reuse.

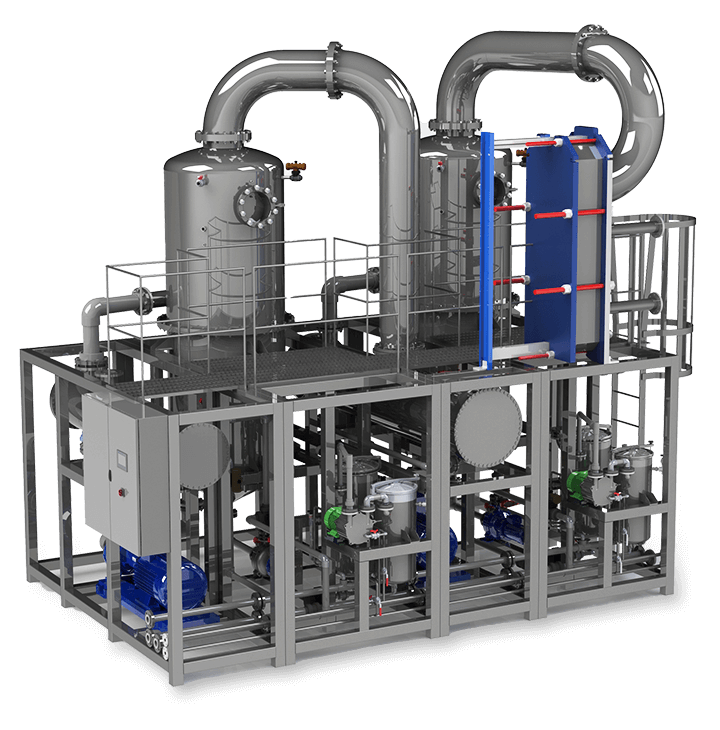

Foundry industry

Foundry operations (sand molding, core making, shakeout, fettling, die-casting support) generate wastewater with high suspended solids (sand fines, slag), oil and grease, metals, binders/resins (phenolic, furan), pigments, and water–glycol mixtures from cooling or hydraulic circuits.