Metal cutting, forming, stamping and surface finishing generate stable oil–water emulsions that are difficult and costly to handle. Typical contaminants include mineral oils and additives, fine metal particles, surfactants, and suspended solids.

Aevya vacuum evaporators can process these emulsions directly — without chemical breaking — separating clean distillate from the oil phase under low temperature and vacuum conditions.

This process ensures high-quality water recovery, minimal chemical use, and low maintenance, making it ideal for most small and medium-size plants.

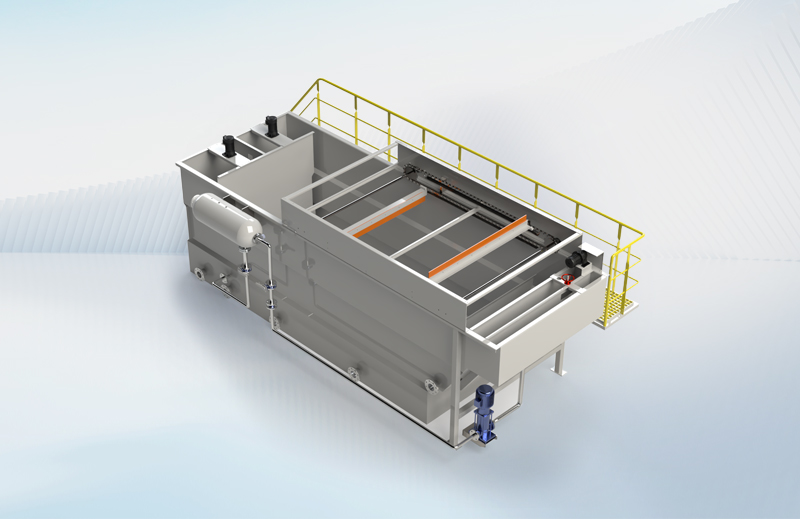

For large wastewater volumes, Deepflow integrates RaeX chemical-physical pretreatment (coagulation and flocculation) to pre-separate bulk oil and solids before evaporation, reducing total operating cost and extending the service interval of the evaporator.

The recovered distillate can be reused as process or rinse water, while the concentrate is collected as a semi-solid sludge for safe disposal or drying with a RedGan low-temperature dryer.