Electroplating, anodizing, and surface finishing lines produce wastewater containing heavy metals, acids, alkalis, and complexing agents, typically from multiple rinse and process baths.

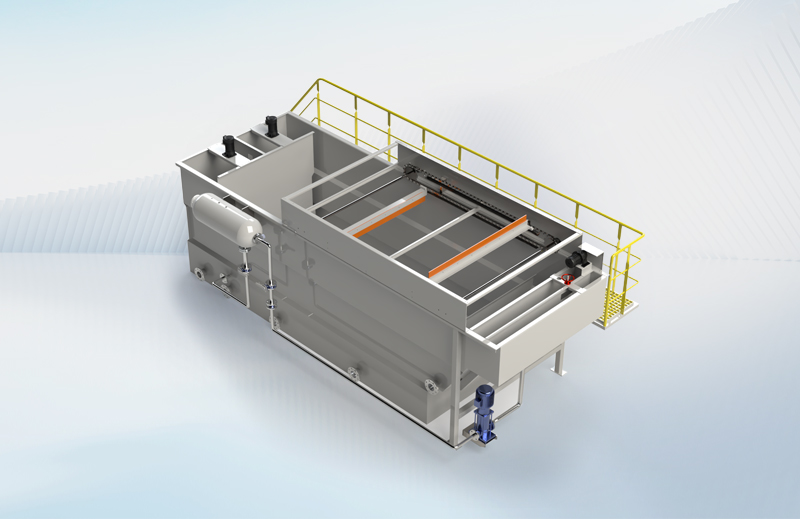

Deepflow provides a flexible, modular approach capable of treating both rinsing waters and active baths, ensuring stable performance and compliance with tightening environmental standards.

For small and medium wastewater volumes, Aevya vacuum evaporators can directly process mixed rinsing waters — without the need for chemical neutralization — producing high-purity distillate that can be reused directly in rinse tanks.

For larger flow rates, the system combines RaeX neutralization and metal precipitation with Aevya evaporation to concentrate the salts and recover clean water for reuse or discharge.

When handling aggressive or high-acid streams, Deepflow systems can be built entirely from Super Duplex 2507 or Titanium Grade 2, ensuring long-term corrosion resistance even in continuous exposure to strong acids such as HCl, H₂SO₄, or HNO₃.