The photovoltaic manufacturing process produces wastewater containing hydrofluoric acid (HF), nitric acid (HNO₃), phosphoric acid (H₃PO₄), and alkaline cleaning agents, along with silica fines and heavy metals from wafer texturing, etching, and polishing operations.

These waste streams are highly corrosive, chemically unstable, and vary significantly across different process lines, which makes conventional treatment difficult to operate reliably.

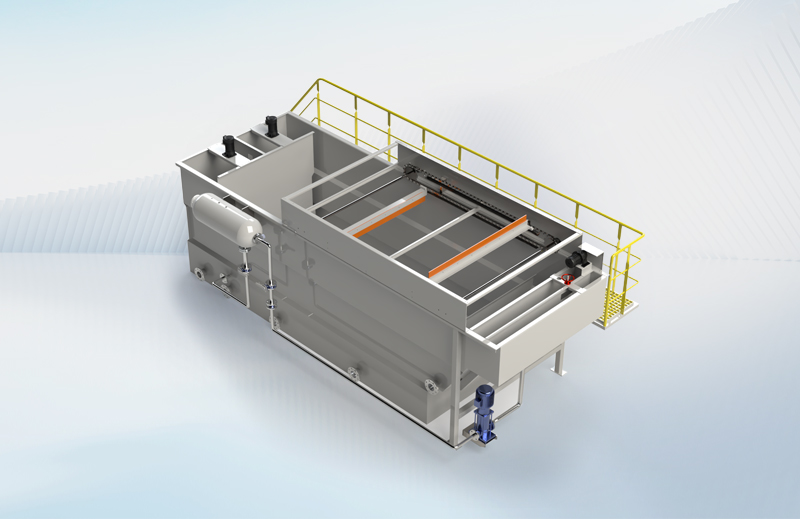

Deepflow provides modular, integrated treatment systems specifically designed for the solar wafer, cell, and module manufacturing industry.

Our solutions combine RaeX chemical-physical neutralization, Seltra membrane filtration, and Aevya or PFET evaporation to ensure efficient removal of fluorides, suspended solids, and heavy metals, while minimizing chemical consumption and maintenance effort.

For large volumes of rinsing water, the PFET polymer-film evaporator offers excellent anti-scaling performance, low energy use, and stable long-term operation.