The printing and photography sectors generate wastewater containing inks, solvents, surfactants, developers, fixers, and residual metals (silver, chromium, nickel).

These effluents are often colored, oily, and highly variable, requiring advanced treatment to ensure compliance and reuse.

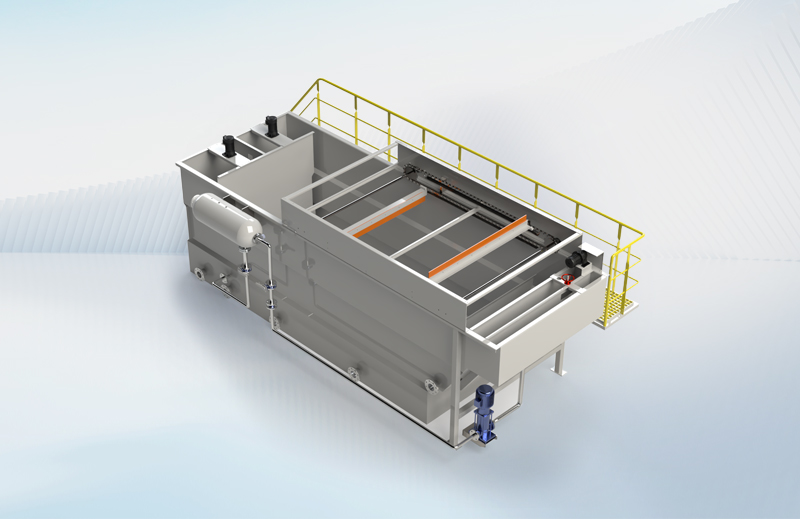

Deepflow provides modular integrated systems that combine chemical precipitation, activated carbon adsorption, membrane separation, and vacuum evaporation, achieving both color removal and heavy metal reduction.

For high-volume rinse or plate-cleaning water, the PFET polymer-film evaporator offers a cost-effective and corrosion-resistant solution, while Aevya vacuum evaporators handle more concentrated developer or fixer solutions.