Landfill leachate contains high concentrations of organic compounds, ammonia nitrogen, salts, and heavy metals, often mixed with surfactants and persistent organic pollutants.

Its composition varies significantly with rainfall, landfill age, and waste composition, making stable treatment a major technical challenge.

Deepflow provides integrated modular systems that combine biological treatment, advanced oxidation, membrane filtration (including DTRO), and vacuum evaporation to achieve reliable compliance and water reuse.

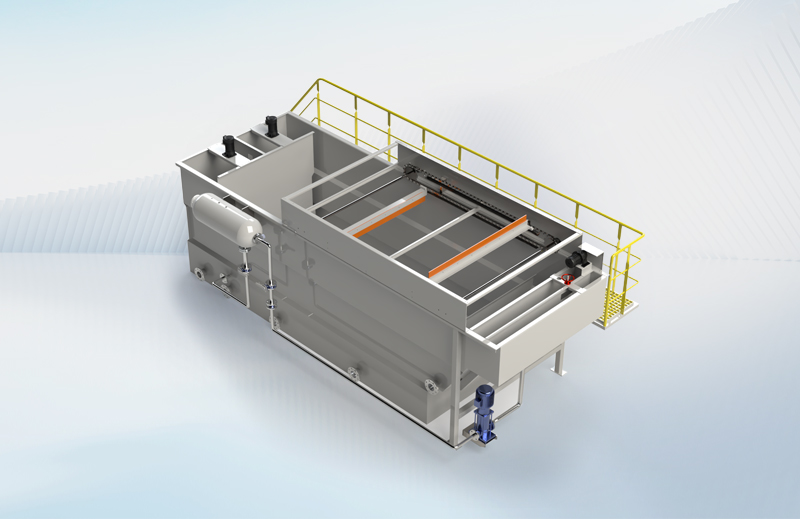

For large leachate volumes, our PFET polymer-film evaporators deliver outstanding energy efficiency and corrosion resistance.

When ammonia or salinity levels are extremely high, Aevya vacuum evaporators ensure reliable separation and distillate purity.