Textile dyeing, washing, and finishing lines produce wastewater containing colorants, surfactants, fiber residues, sizing agents, and salts. These streams are often strongly alkaline or acidic, and highly variable in temperature and organic load.

Deepflow provides complete, automated solutions combining chemical-physical pretreatment, membrane separation, and vacuum evaporation, ensuring stable and compliant operation even under fluctuating conditions.

For medium to high concentrations, Aevya vacuum evaporators safely concentrate wastewater from dyeing or rinsing processes, while RaeX modules manage pH stabilization and suspended solids removal.

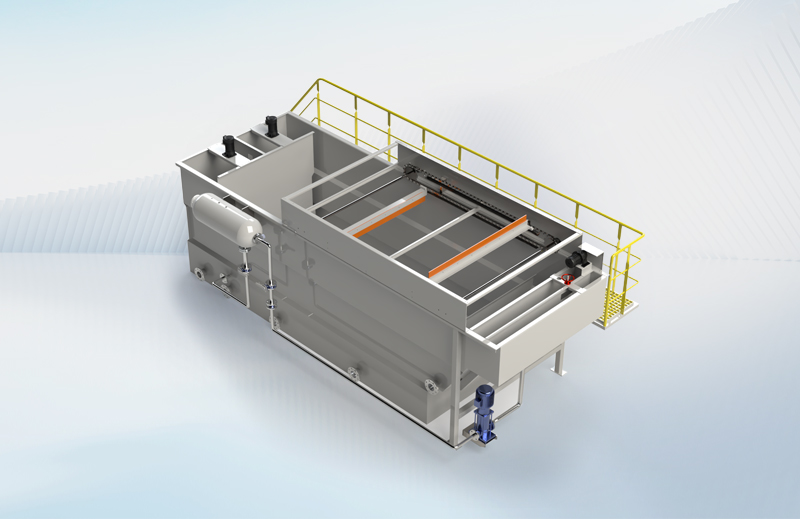

For large wastewater volumes, the PFET (Polymer Film Evaporation Technology) series offers an exceptionally efficient and sustainable solution.

Its plastic corrosion-resistant heat exchangers make it ideal for treating aggressive textile rinsing waters containing acids, alkalis, or oxidizing agents — with low energy consumption and minimal maintenance requirements.

In both cases, the purified distillate can be reused directly in washing, bleaching, or finishing operations, significantly reducing freshwater consumption and discharge volumes.

When operating under severe chemical or colorant conditions, Deepflow systems can also be built in Super Duplex 2507 or Titanium Grade 2, ensuring maximum durability and chemical stability.