pharmaceutical wastewater

Pharmaceutical production generates wastewater containing high concentrations of organics, solvents, antibiotics, and residual active compounds.

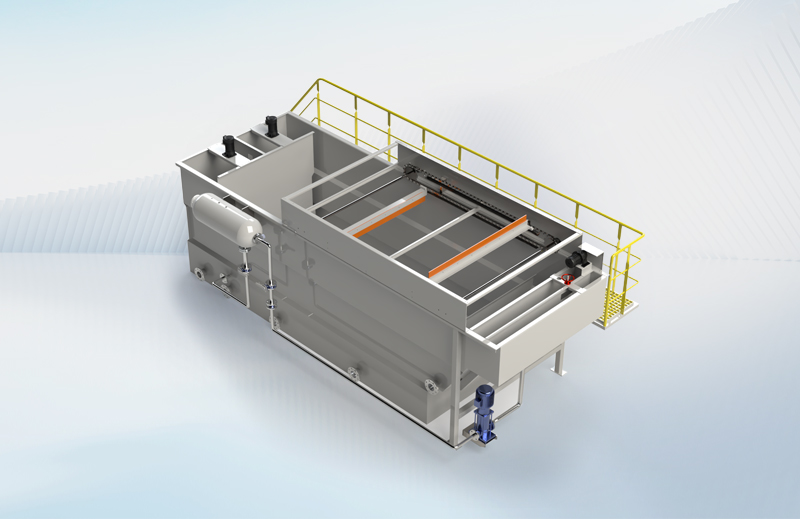

Deepflow provides complete solutions to handle these challenging streams, combining physical-chemical pretreatment, membrane separation, and vacuum evaporation for reliable, compliant, and sustainable operation.

Our systems are designed to meet the strictest discharge limits and GMP environmental standards. Whether the process involves chemical synthesis, fermentation, or washing of equipment and containers, Deepflow ensures that the effluent is treated safely — protecting both the environment and product integrity.

In particular, Aevya evaporators efficiently concentrate streams containing high organic or saline loads, while Seltra membrane systems remove residual compounds for reuse or compliant discharge.

For high-volume, diluted wastewater from cleaning operations, PFET polymer-film evaporators offer excellent performance with corrosion-resistant polymer heat exchangers, ideal for aggressive or variable compositions.

.jpg)