Leather production and tanning generate wastewater containing chromium, sulfides, organic pollutants, dyes, and high salinity.

These effluents are highly loaded, variable in composition, and can cause severe environmental impact if not properly treated.

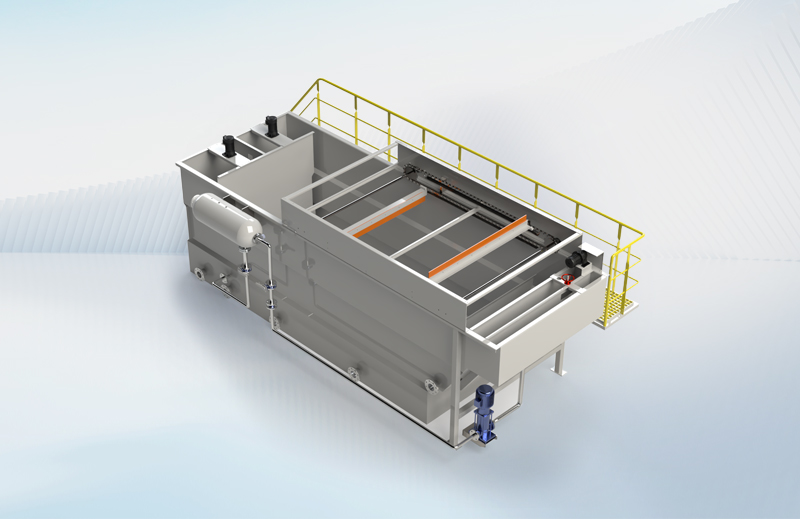

Deepflow provides complete and modular treatment systems combining chemical precipitation, biological treatment, membrane separation, and vacuum evaporation, ensuring safe disposal or internal water reuse.

For tanneries with large daily volumes of wastewater, our PFET polymer-film evaporators offer an ideal solution — highly efficient and corrosion-resistant, thanks to polymer heat exchangers that handle acidic and saline conditions without fouling.