Foundry operations (sand molding, core making, shakeout, fettling, die-casting support) generate wastewater with high suspended solids (sand fines, slag), oil and grease, metals, binders/resins (phenolic, furan), pigments, and water–glycol mixtures from cooling or hydraulic circuits.

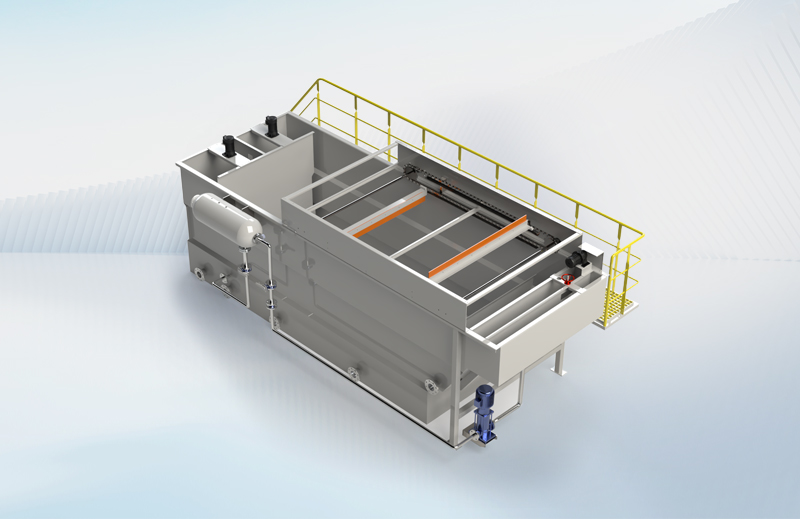

Deepflow delivers modular, integrated systems that stabilize the flow, remove solids and oil, and concentrate dissolved loads for reuse or compliant discharge.

For large flow rates (e.g., rinsing, floor wash, cooling loops), PFET polymer-film evaporators provide energy-efficient concentration. Their plastic heat exchangers are highly resistant to aggressive species and scaling, ideal for foundry wash waters. For more concentrated streams, Aevya vacuum evaporators deliver clear distillate with minimal chemical use.